产品详情:

CJJ系列·全陶瓷无污染机械式粉碎机

(CJJ series · All ceramic non-contamination mechanical pulverizer)

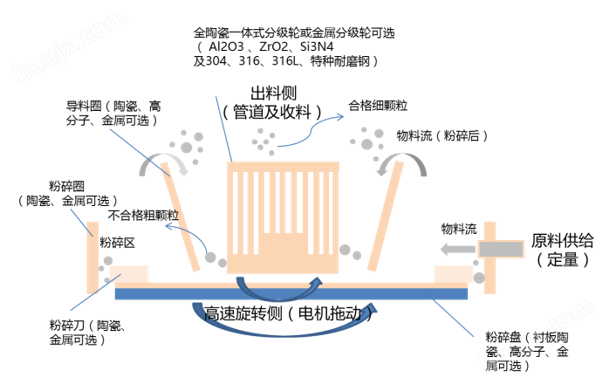

工作原理:

物料被定量加入粉碎腔后,高速旋转的粉碎盘产生的气流涡旋会将物料带入粉碎盘与齿圈之间的间隙中,粉碎盘上安装有粉碎刀片,刀片与齿圈高速剪切,物料由粗变细,之后在负压的作用下,进入内置的分级腔内,接受高速分级轮的筛选,合格细粉会通过分级轮继而通过管道进入后道收尘设备(旋风分离器、布袋除尘器等),粒度仍然不下落被重新冲击破碎。

working principle:

After the material is quantitatively added to the crushing cavity, the airflow vortex generated by the high-speed rotating crushing disk will bring the material into the gap between the crushing disk and the ring gear. The crushing blade is installed on the crushing disk, and the blade and the gear ring are sheared at high speed. The material changes from coarse to fine, and then enters the built-in classification chamber under the effect of negative pressure, and is screened by the high-speed classifying rotor. The qualified fine powder will pass through the classifying rotor and then enter the downstream dust collection equipment (cyclone separator, bag filter, etc.) through the pipeline, those particle size which still does not reach the standard will be impacted and broken again.

设备特点:

- 结合“机械冲击”与“气流涡旋”的作用,相比气流粉碎,破碎强度适中,不易产生过粉碎现象,能耗大大降低;

- 粉碎、分级一体式设计,高速分级轮结合特殊的密封结构,产品出料粒度均匀可控、分布范围窄且无大颗粒混入;

- 主机内腔接触物料部位全部工程陶瓷防护,从而满足多数高新材料避免金属杂质污染要求,关键部位包括进料机构、齿圈、粉碎刀、分级轮、密封机构、出料机构等,特别是全陶瓷高速分级轮属于我公司产品,经一体加工成型,线速度高,分级粒度精准可控。

- 适用于硬度在5级以下、对过细粉敏感的物料粉碎,另外还可用于烧结处理或干燥后物料的打散解聚,能耗低,产能高;广泛应用于锂电池正负极材料、高新陶瓷材料、电子材料等领域。

- 可根据物料特性,实现低露点闭路循环粉碎;灵活选用合适形式的刀片、齿圈的粉碎副组合,以达到超细化、球形化等不同的粉碎要求;可与涡轮分级机联合使用,再次调整粒度分布。

- 匹配全流程自动化生产线,无粉尘外泄,绿色环保;劳动强度低;智能在线及远程控制;

1. Combining the effects of "mechanical impact" and "airflow vortex", compared with airflow crushing, the crushing strength is moderate, over crushing is not easy to occur, and energy consumption is greatly reduced;

2. The integrated design of crushing and grading, high-speed classifying rotor combined with special sealing structure, the product discharge particle size is uniform and controllable, the distribution range is narrow and no large particles are mixed;

3. All engineering ceramics in the cavity of the main unit are in contact with the material to protect it, so as to meet the requirements of most high-tech materials to avoid metal impurity contamination. The key parts include the feeding mechanism, ring gear, crushing knife, classifying rotor, sealing mechanism, discharging mechanism, etc., especially The all-ceramic high-speed classifying rotor belongs to our company's patented product. It is formed by one-piece processing, with high linear speed and accurate and controllable grading granularity.

4. It is suitable for crushing materials with hardness below 5 and sensitive to excessively fine powder. It can also be used for disintegration and disaggregation of materials after sintering or drying, with low energy consumption and high production capacity; widely used in positive and negative materials of lithium batteries , High-tech ceramic materials, electronic materials and other fields.

5. According to the characteristics of the material, it can realize the low dew point closed-circuit crushing; flexibly choose the appropriate combination of blade and gear ring crushing combination to achieve different crushing requirements such as ultra-fine and spherical; can be used in combination with the turbine classifier Adjust the particle size distribution again.

6. Match the whole process automated production line, no dust leakage, green environmental protection; low labor intensity; intelligent online and remote control;

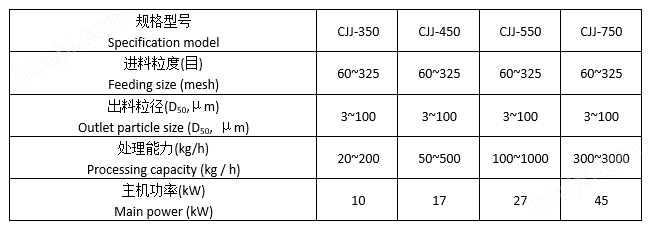

技术参数表(Technical Data Sheet)

注:具体配置及处理效果需根据物料性质与加工要求确认,可与我司工程师沟通或来料试验。

Note: The specific configuration and processing effect need to be confirmed according to material properties and processing requirements, and youcan communicate with our engineers or come to do materials processing test first.

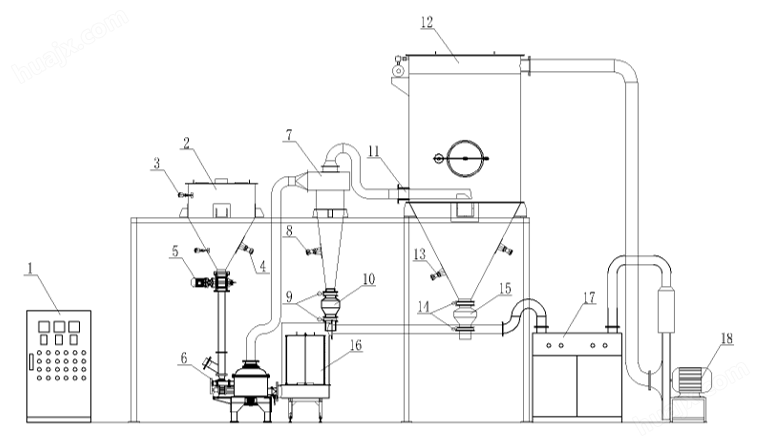

实物图片(Physical picture)

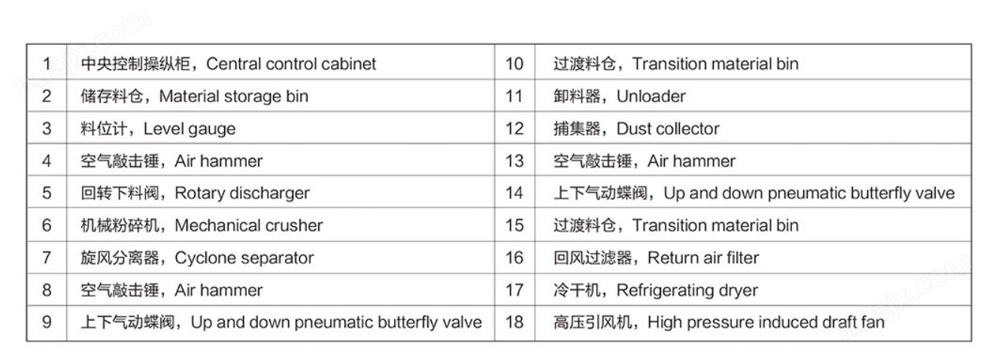

参考工艺流程图(Reference process flow chart)

团体标准《全陶瓷无金属污染机械式超细粉碎机》标准编号:T/JSP2-2019

Group Standard "All-ceramic No Metal Contamination Mechanical Ultra-micro Crusher"标准编号:T/JSP2-2019