MONO莫诺螺杆泵 Widethroat(宽喉道)W 泵系列产品

MONO莫诺螺杆泵 Widethroat(宽喉道)W 泵系列产品设计用于输送高粘度的物料,

例如粘度高于 1,000,000cP 的淤泥、淤浆、无流动性稠糊浆和脱水污泥块。这款螺杆泵标准设计包括一个扩大的矩形入口,配有一个螺旋输送器协助产品进入泵芯。

可有不同选项用于修改入口以适合任何大口径的螺旋推运器、一体化防堵器或两者同时进行。

| 容量 | 压力 | 温度 | |||

|---|---|---|---|---|---|

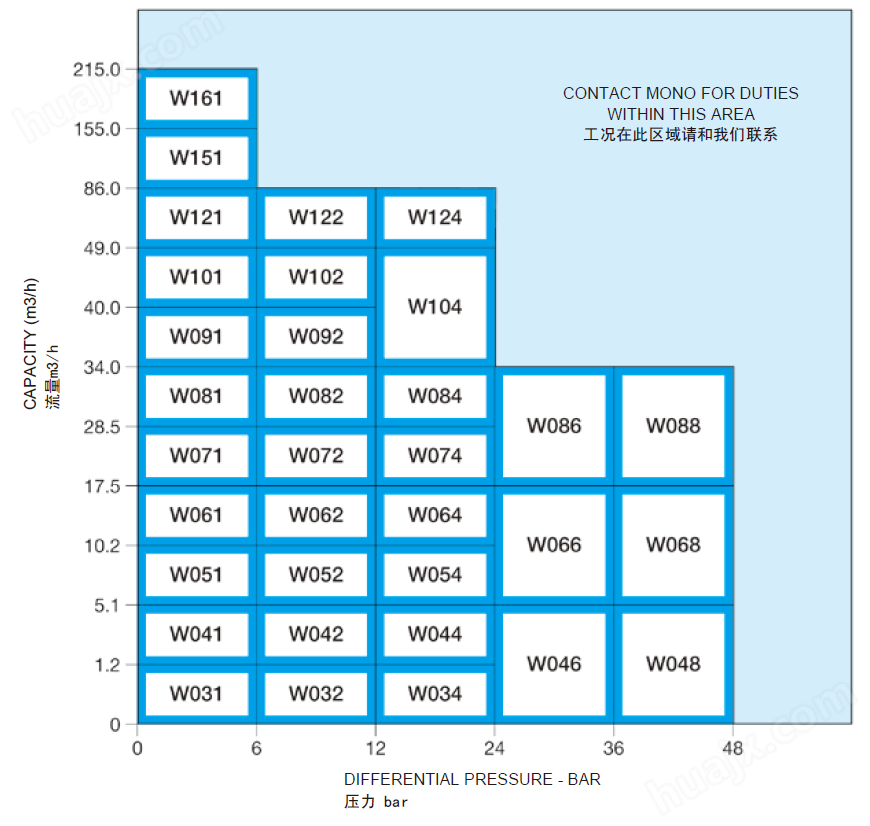

| 立方米 / 小时 | 可达 215 | bar | 可达 48 | °C | -10 到 100 |

| 加仑 / 分钟 | 可达 946 | psi | 可达 700 | °F | 14 到 212 |

点击快速查看以下内容

MONO莫诺螺杆泵 Widethroat(宽喉道)W 泵系列产品特性与优点

MONO莫诺螺杆泵 Widethroat(宽喉道)W 泵系列产品 性能

MONO莫诺螺杆泵 Widethroat(宽喉道)W 泵系列产品 应用

MONO莫诺螺杆泵 Widethroat(宽喉道)W 泵系列产品 尺寸

MONO莫诺螺杆泵 Widethroat(宽喉道)W 泵系列产品应用

| 淤泥 | 淤浆 |

| 无流动性稠糊浆 | 脱水污泥块 |

| 肉馅 | 膨润土泥浆 |

| 制药滤饼 | 鸡内脏 |

| 马铃薯废泥浆 | 高粘度的物料 |

MONO莫诺螺杆泵 Widethroat(宽喉道)W 泵系列产品特性与优点

- 提供一种工艺上有效的方法,输送有高固体含量的淤浆

- 不同的设计配置以适合具体应用,在安装了一体化的防堵器或者大的螺旋推运器时,接近 40% 干燥固体的也可以输送

- 由于设计简单以及在轴上使用塞子方便维修

- 设计在相对低的速度运行最大程度减少对剪切敏感产品的损坏

- 可用泵有 monobloc 或 bareshaft

- 可提供一台 Muncher 研磨机,水平安装到料斗前以减少在输送前的固体物

- 可提供符合 ATEX 指令 94/9/EC 的泵

The design of the W range is such that many different applications can be handled. The standard design consists of an enlarged

rectangular inlet with a screw conveyor to assist the product into the pumping element. Options exist that can modify the inlet with

either large diameter augers, integral bridge breakers or both.

Pumps are available in most cases as Monobloc® (close coupled) or as a bareshaft pump.

Dry solids approaching 40% can be handled by the pumps when fitted with either the integral bridge breakers or large augers.

The pump has been designed to facilitate maintenance through its simple design and the use of a plug in shaft facility.

The pumps are available in a range of materials to ensure a wide variety of products can be handled. Shaft sealing is a hard faced,

single mechanical seal, with packed gland available as an option.

The Widethroat r

The Widethroat r

ange has been designed to handle highly viscous materials such as sludges, slurries, thick non-flowing pastes

and de-watered sludge cake with viscosities up to 1,000,000 cP.

The range is based on single, two, four, six and eight stage pumps which can develop pressures up to 48 bar and capacities up

to 215m3/h.

For the many difficult and varied applications encountered, the pumps are run at a relatively slow speed, therefore the pump will

handle shear sensitive products with minimal product damage, abrasive solids in suspension and highly viscous materials

点击快速返回顶层

点击快速返回顶层

MONO莫诺螺杆泵 Widethroat(宽喉道)W 泵系列产品 性能

NOTES:

1. The tabulated performance data shown is based upon handling clean water at 20oC.

2. For guidance in selection of a pump for use with other fluids of varying abrasion and viscosity refer to Mono Pumps Ltd.,

Audenshaw, Manchester.

点击快速返回顶层

点击快速返回顶层

MONO莫诺螺杆泵 Widethroat(宽喉道)W 泵系列产品应用

A W064 model installed at a sewage treatment works to control sewage

odours, caused by a belt press feeding dewatered sludge cake directly

onto an open-air conveyor and into an open skip for disposal. The cast

iron W064, with an integral bridge breaker fitted as an option, delivers

the sludge cake at the required rate of 2.5m3/h and pressures of up to 12

bar. It operates eight hours per day, six days a week and daily fills up the

four enclosed skips with sludge cake.

Problems arose at a water treatment works with the discharge of sludge

cake by chute into a skip for disposal on landfill sites. As the

sludge is a relatively im solid, the only way to load the skip evenly

was by manually raking it out. The installation of a W054 pump loads the

kip via a 15 metre long, 150mm diameter flexible hose, and the nonpulsating

nature of the pump provides an even output of 1.5m3/h. As the

pump operates at a pressure of 1 bar, it compresses the

cake still further. Significant cost savings are achieved as a result - the

skip now holds 6 tonnes rather than 4.5.

A custom-built W082 is speeding up waste disposal at a Scottish

tannery. Previously the ‘fleshings’ were shovelled manually from the

processing area to a skip, this method was highly labour intensive. The

cast iron W range pump with large auger and hopper were specially

modified in order to handle this difficult material. The fleshings waste is

gravity fed into the hopper, then pumped at 5.5m3/h at a pressure of 3

bar, along 30m of pipe direct to an outside skip for disposal.

A total of 9 stainless steel W range pumps have been installed at a plant

in Greenwich to handle highly viscous materials and transfer it along

several hundred metres of pipework. Operating at speeds of between

123rpm and 196rpm, delivering gluten at a capacity of 4.5m3/h to

40.5m3/h and pressures of 3 to 8 bar. Extreme reliability was specified

by the customer, as the pumps have to operate 24 hours a day, seven

days a week with minimum downtime for repairs.

A customer, producing mechanically deboned meats, which are frozen

before export to food manufacturers worldwide, has installed a stainless

steel W062 pump. The meat puree is gravity fed into the inlet hopper for

transfer to the freezer plates. The efficiency of the freezing system relies

on a constant flow rate of 5 tonnes per hour, to prevent the plates standing

idle or a delay further up the line.

This site’s sludge dewatering unit, installed at a large sewage treatment

works, is a belt thickening system, comprising 3 x 3m wide belt of 0.7mm

mesh, located above a collection sump. As the dewatered sludge

reaches the end of the belt it is deposited into the inlet hopper of the

W072 pump and transferred to holding tanks at 14m3/h. Ideal for thick

non-flowing sludges and slurries the W range incorporates an auger

system which help to feed the sludge to the pumping element without

bridging or blocking.

A leading designer and manufacturer of machinery for producing

savoury pies, pasties and sausage rolls is incorporating stainless steel

W032 pumps into its sausage roll manufacturing machines. Transferring

prepared sausage meat in a continuous uniform length to the pastry

casing at a capacity of between 5-10m3/h, the W range features an

auger feeding system to ensure the sausage meat is consistently fed

from the extended hopper inlet to the pumping element.

点击快速返回顶层

点击快速返回顶层

MONO莫诺螺杆泵 Widethroat(宽喉道)W 泵系列产品 尺寸

MODEL STANDARD + BRIDGE BREAKER STD LARGE AUGER ALLMODELS

Y A V x W S S1 Y A V x W S D

W032 720 1156 320 x 170 185 *

W034 750 1638 320 x 170 212 50

W041 835 1324 350 x 250 232 65

W042 835 1523 350 x 250 232 412 770 1842 750 x 250 282 65

W044 890 1987 350 x 250 245 425 880 2293 750 x 250 295 80

W051 500 x 250 247 80

W052 500 x 250 260 435 770 2010 750 x 250 310 80

W054 500 x 250 285 460 765 2657 750 x 250 335 100

W061 650 x 360 285 100

W062 650 x 360 310 515 1000 x 360 375 100

W064 650 x 360 320 525 1000 x 360 395 125

W071 650 x 360 330 125

W072 650 x 360 330 525 1000 x 360 415 125

W074 650 x 360 405 600 1000 x 360 465 125

W081 650 x 360 330 125

W082 650 x 360 340 550 1000 x 360 505 125

W084 650 x 360 405 615 1000 x 360 505 150

W091 800 x 450 360 150

W092 800 x 450 360 575 1000 x 450 505 150

W101 800 x 450 360 150

W102 800 x 450 405 655 1000 x 450 550 150

W121 800 x 450 450 200

NOTES

MONO莫诺螺杆泵 Widethroat(宽喉道)W 泵系列产品 相关咨询欢迎您的来电

MONO莫诺螺杆泵 Widethroat(宽喉道)W 泵系列产品 相关咨询欢迎您的来电