一、ZW型自吸式无堵塞排污泵产品概述:

ZW型自吸式无堵塞排污泵,是本司根据ZX型自吸离心泵及QW型潜水排污泵的结构及性能,借鉴国外同类产品之优点,研制而成的集自吸及排污于一身的新型泵种。既可象一般清水自吸泵那样不需安装底阀,不需灌引水,又可抽吸含有大颗粒固体直径为出口口径的60%和纤维长度为叶轮直径1.5倍的污物、沉淀物、废矿杂质、粪便处理及一切工程污水物和胶质液体,*减轻人力的劳动强度,而且安装使用方便,极少维修,性能达到水平,具有广阔的应用市场和发展前景

本司产品全部采用计算机设计和优化处理,公司拥有雄厚的技术力量、丰富的生产经验和完善的检测手段,从而保证产品质量的稳定可靠。

二、ZW型自吸式无堵塞排污泵适用范围:

适用于化工、石油、制药、采矿、造纸、纤维、浆料、纺织、食品、电厂及市政排污工程、公共设施排污、河塘养殖等行业。

三、ZW型自吸式无堵塞排污泵产品优点:

1、排污能力强:特殊的叶轮防堵设计,确保了泵高效且无堵塞。

2、高效节能:采用优秀水力模型,效率比一般自吸泵高3~5%。

3、自吸性能好:自吸高度比一般自吸泵高1米,且自吸时间更短。

四、ZW型自吸式无堵塞排污泵技术参数:

流量:5-800m3/h;

扬程:12-60m;

电机功率:2.2-55KW;

转速:1450-2900r/min;

口径:φ25-φ300;

介质温度:≤100℃;

自吸高度:4.5-6.0m。

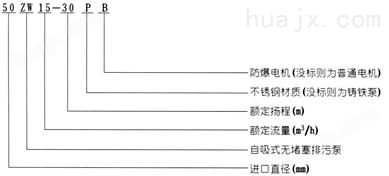

五、ZW型自吸式无堵塞排污泵型号意义:

六、ZW型自吸式无堵塞排污泵性能参数:

| 类型 | 流量M3/H | 扬程(m) | 功率(kw) | 转速(r/min) | 效率(%) | 汽蚀余量(m) | 自吸高度(m) | 自吸时刻(min/S) | 分量(kg) |

| ZW25-8-15 | 8 | 15 | 2.2 | 2900 | 45 | 2.0 | 5.5 | 3 | 100 |

| ZW32-5-20 | 5 | 20 | 2.2 | 2900 | 46 | 2.5 | 5.5 | 3 | 100 |

| ZW32-10-20 | 10 | 20 | 2.2 | 2900 | 45 | 2.5 | 5.5 | 3 | 100 |

| ZW32-9-30 | 9 | 30 | 3 | 2900 | 48 | 2.5 | 5.5 | 3 | 120 |

| ZW40-10-20 | 10 | 20 | 2.2 | 2900 | 45 | 2.5 | 5.5 | 3 | 100 |

| ZW40-20-15 | 20 | 15 | 2.2 | 2900 | 45 | 2.5 | 5.5 | 3 | 100 |

| ZW40-15-30 | 15 | 30 | 3 | 2900 | 48 | 2.5 | 5.5 | 3 | 120 |

| ZW50-10-20 | 10 | 20 | 2.2 | 2900 | 45 | 2.5 | 5.5 | 3 | 100 |

| ZW50-20-12 | 20 | 12 | 2.2 | 2900 | 45 | 2.5 | 5.5 | 3 | 100 |

| ZW50-15-30 | 15 | 30 | 3 | 2900 | 48 | 2.5 | 5.5 | 3 | 120 |

| ZW50-20-35 | 20 | 35 | 5.5 | 2900 | 48 | 2.5 | 5.5 | 3 | 150 |

| ZW65-30-18 | 30 | 18 | 4 | 1450 | 45 | 2.5 | 5.5 | 3 | 200 |

| ZW65-25-30 | 25 | 30 | 5.5 | 2900 | 50 | 3.0 | 5.5 | 3 | 200 |

| ZW65-25-40 | 25 | 40 | 7.5 | 2900 | 50 | 3.0 | 5.5 | 2 | 200 |

| ZW65-40-25 | 40 | 25. | 7.5 | 2900 | 50 | 3.0 | 5.5 | 2 | 200 |

| ZW65-65-25 | 65 | 25 | 7.5 | 2900 | 52 | 3.0 | 5.5. | 2 | 240 |

| ZW80-40-16 | 40 | 16 | 4 | 1450 | 50 | 3.0 | 5.0 | 3 | 240 |

| ZW80-40-25 | 40 | 25 | 7.5 | 2900 | 50 | 3.0 | 5.5 | 2 | 200 |

| ZW80-25-40 | 25 | 40 | 7.5 | 2900 | 50 | 3.0 | 5.5 | 2 | 200 |

| ZW80-65-25 | 65 | 25 | 7.5 | 2900 | 52 | 3.0 | 5.5 | 2 | 240 |

| ZW80-80-35 | 80 | 35 | 15 | 2900 | 45 | 3.0 | 5.5 | 3 | 285 |

| ZW80-40-50 | 80 | 40 | 18.5 | 2900 | 50 | 3.0 | 5.5 | 2 | 293 |

| ZW80-50-60 | 50 | 60 | 22 | 2900 | 55 | 3.0 | 5.0 | 3 | 326 |

| ZW100-100-15 | 100 | 15 | 7.5 | 1450 | 50 | 4.0 | 5.5 | 3 | 300 |

| ZW100-8020 | 80 | 20 | 7.5 | 1450 | 53 | 4.0 | 5.5 | 3 | 300 |

| ZW100-100-20 | 100 | 20 | 11 | 1450 | 53 | 4.0 | 5.5 | 3 | 340 |

| ZW100-100-30 | 100 | 30 | 22 | 2900 | 53 | 4.0 | 5.5 | 2 | 510 |

| ZW100-80-45 | 80 | 45 | 30 | 2900 | 55 | 4.0 | 5.5 | 2 | 560 |

| ZW100-80-60 | 80 | 60 | 37 | 2900 | 53 | 4.0 | 5.5 | 2 | 585 |

| ZW100-80-80 | 80 | 80 | 45 | 2900 | 50 | 4.0 | 5.5 | 2 | 639 |

| ZW125-120-20 | 120 | 20 | 15 | 1450 | 55 | 4.5 | 5.5 | 2 | 500 |

| ZW150-180-14 | 180 | 14 | 15 | 1450. | 60 | 5.0 | 5.5 | 3.5 | 500 |

| ZW150-180-20 | 180 | 20 | 22 | 1450 | 60 | 5.0 | 5.0 | 3 | 570 |

| ZW150-180-30 | 180 | 30 | 37 | 1450 | 65 | 5.0 | 5.0 | 3 | 680 |

| ZW150-180-38 | 180 | 38 | 55 | 1450 | 45 | 5.0 | 6.0 | 3.5 | 800 |

| ZW200-280-14 | 280 | 14 | 22 | 1450 | 65 | 5.0 | 5.0 | 3 | 820 |

| ZW200-280-20 | 280 | 20 | 37 | 1450 | 62 | 5.0 | 5.0 | 3 | 910 |

| ZW200-300-25 | 300 | 25 | 45 | 1450 | 59 | 5.0 | 5.0 | 3 | 948 |

| ZW200-280-28 | 280 | 28 | 55 | 1450 | 55 | 4.8 | 5.2 | 3 | 1090 |

| ZW250-420-20 | 420 | 20 | 55 | 1450 | 61 | 6.0 | 4.5 | 2.5 | 1150 |

| ZW300-800-14 | 800 | 14 | 55 | 1450 | 65 | 6.0 | 4.5 | 2.5 | 1400 |

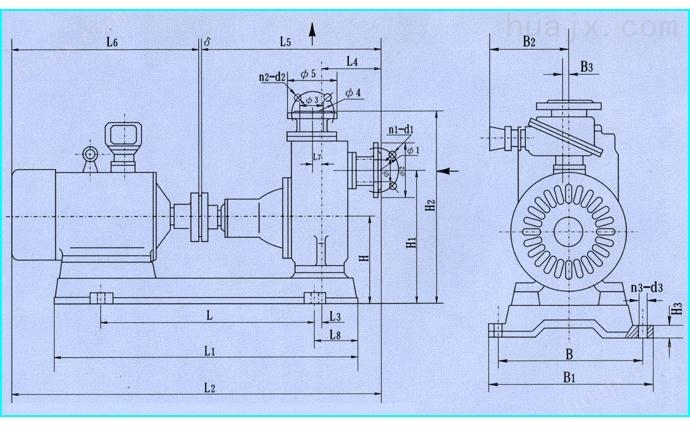

ZW型自吸式无堵塞排污泵外形安装尺寸

ZW型自吸式无堵塞排污泵曲线图谱

ZW型自吸式无堵塞排污泵故障及排除

| 故 障 | 产 生 原 因 | 排 除 方 法 |

| 泵不出水 | 1、 泵体储液不足 2、 吸入管路漏气 3、 转速太低 4、 泵反转 5、 吸入太高或吸入管路太长 | 1、 加足 2、 检查并排除泄漏现象 3、 调整电源电压 4、 检查纠正 5、 降低吸程和缩短管路 |

| 出水量不足 | 1、 因使用不当,吸入管路被堵塞 2、 功率不足转速太低 3、 出水阀门开度太小 | 1、 堵塞物 2、整额定转速 3、大开度 |

| 泵噪音、振动过大 | 1、 底脚不稳 2、 轴承严重磨损 3、 吸程过高 4、 流量太大 | 1、 加固 2、 更换轴承 3、 降低吸程 4、 控制流量 |

| 轴承升温过高 | 1、 轴承损坏 2、 润滑脂变质或干燥 | 1、 更换 2、 更换润滑脂 |

| 泵泄漏 | 1、 机械密封件损坏 2、 联接螺栓松动 | 1、 更换 2、 加固 |